Cone crusher spare parts is manufactured with high manganese steel Mn13Cr2, Mn18Cr2, Mn22Cr2 or Manganese steel with special alloy and heat-treatment process. Cone crusher spare parts has a working life of 10%-15% longer than those made of traditional manganese steel.

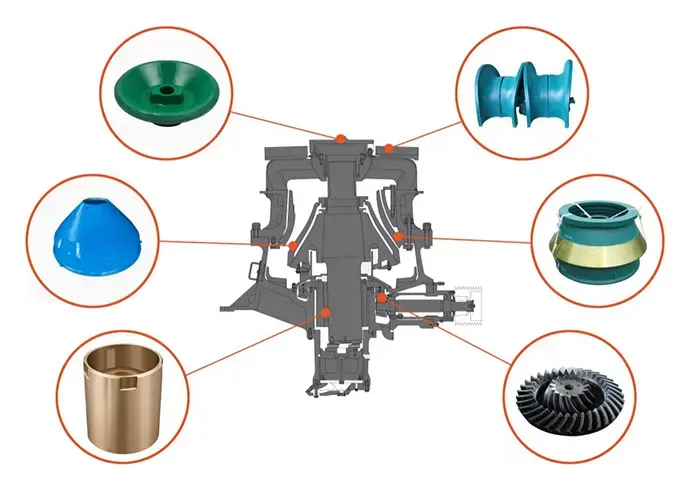

Bowl Liner | Concave

Bowl Liner in another name concave Ring , Is a fixed unit accommodate on the bowl assembly. It is a sacrificial liner to squeezing the rock passively by the rotating mantle assembly.

Normally the bowl liner having options of different cavities according to the material requirement, like (Extra Coarse), C(Coarse), M(Medium), F(Fine) and EF(Extra Fine).

Each type of cone crusher having different design of the bowl liner, some are fixing by the taper wedge and some by the U-Bolt, and many copies with small changes available at the market. We having full data of all popular models cone crushers and our engineers real know how to select the right bowl liner to your machine.

Mantle

The Mantle is a moving unit seat on the cone mantle assembly, It is rotates decentralization by the Eccentric assembly. The mantle is a positive sacrificial liner squeezing the rock to the bowl until it get to the small size to be release from the gap between mantle and concave.

The Mantle also having standard and shorthead type with selections of coarse ,medium and fine according to different type of cone crusher, But it not has as much as bowl liners normally the spring cone crusher the mantle is replaceable between the same model of crushers, but for the hydraulic cone crushers it also having different mantles to get more specific size and different crushing applications.

Generally the mantle looks same but small difference on the curve and height can result irreplaceable with your machine or big gap which result the vibrations during operations. We having full data of all popular models cone crushers and our engineers real know how to select the right bowl liner to your machine.

Distribution | Feed Plate

The Distribution plate in another name as feeding plate is fixing on top mantle assembly with joint with locking nut. made of high Maganese steel normally Mn13cr2 or Mn18cr2 The function is distribution the rock uniformity to the side of the crushing chamber and protect the rock to wear the Tighten nut and cutting ring which is made out of Carbon steel. Different models of crusher having different design of the Feed plate, as it is a regular changing small parts Casteel keep stcoks of it covers most popuar crusher models like HP, GP, PYB, Symons, TC and SBS Series as etc.

Arm Shield | Guards

The Arm Shield also as know of Arm Guards or Arm Liner, Made of High Manganese steel it is mainly using on the Single cylinder cone crusher and gyratory crusher, It is to protect The Spider assembly when the rock directly feeding to the top of crusher.

Another liner name Narrow Arm Liner is seat below the lower frame it is to protect the lower frame body wear out by the discharged material at the bottom. The narrow are liner normally to have a bigger one around countershaft and 2 small one at the lower arms.

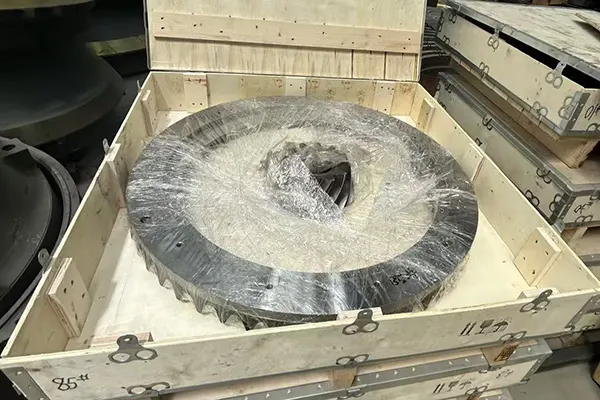

Gear and Pinion

Pinion and gear are the critical components in cone crushers, which convert rotational energy from the motor into the crushing motion of the cone (head).

We use high-strength alloy steel for gears, including 42CrMo; 17CrNiMo6; 20CrMoTi; 40CrNiMo; 40CrNi2Mo, and other materials, or custom-designed gears. Depending on the material and application, we offer various heat treatments, including: quenching and tempering (hardness HB300-330); tooth surface carburizing (hardness HRC ≥ 55, depth 1.5-3 mm); tooth surface ion nitriding (hardness HRC ≥ 55, depth 0.7-1.5 mm); and surface induction hardening (hardness HRC ≥ 55, depth 1-2 mm). Gear accuracy is Class V after tooth surface grinding.

Eccentric Shaft Bushing

The eccentric bushing is a component of a cone crusher that is located at the center of the main shaft. It is used to support the gyratory movement of the main shaft and also serves as a bearing.

The eccentric bushing is made of bronze, which has good wear resistance and can withstand high loads. It is designed to fit snugly onto the main shaft and rotate with it. The inner surface of the eccentric bushing is shaped like a cone, which matches the shape of the main shaft. As the main shaft rotates, the eccentric bushing also rotates, creating the gyratory motion that is characteristic of a cone crusher.

A bushing with normal use tends to wear more at the heaviest side of the eccentric. This is no cause for concern since it is a normal and expected condition, a bushing that is worn excessively thin or cracked will, of course, require replacement.

Mainshaft Step | Piston Wearing Plate

The Piston Wearing Plate is a key, vulnerable part installed on the piston assembly. Its core function is to reduce direct friction between the piston and the cylinder body/other moving parts, withstand impact loads, prevent premature wear of the piston body, and assist in sealing the hydraulic oil, thereby improving the stability of the piston movement and the overall life of the equipment.

Enhanced Dust Seal Rings

The cone Crusher Dust Seal Ring is designed to prevent dust and contaminants from entering the crusher, ensuring smooth operation and longevity . Made from high-quality materials like high manganese steel, these rings provide excellent wear resistance and strength . They are compatible with various crusher models, including Metso, Terex, and Sandvik, ensuring a secure fit and reduced downtime.