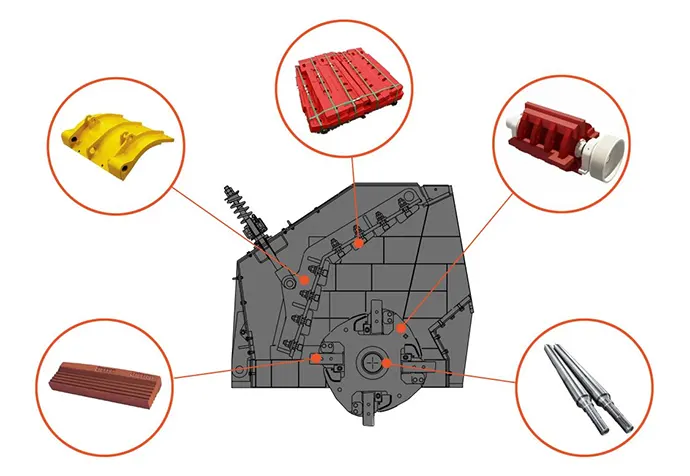

Impact crusher spare parts is manufactured with high chrome white iron steel Cr20, Cr26, Cr28, Cr30 or high chrome with special alloy, which employ the external refining technology effectively reduced the harmful elements, impurity, oxygen and hydrogen harm, greatly enhanced the abrasion resistance and impact toughness of the steel.

Impact Plate

The impact plate also calling as breaker plate or Apron Liner which is lining the upper middle and lower of the crushing chamber. is the second vulnerable part in the impact crusher to the plate hammer, which bears a high-velocity impacts. The shape and material the impact plate have a great influence on the impact breaking efficiency and service life.

Our impact plates available in monometallic alloys as well as in Metal Matrix Composite (MMC) solutions combining the hardness of ceramic with the useful mechanical properties of cast iron or steel, considerably increasing the life span of the parts and the productivity of the crusher.

We can provide a variety of styles, and choose high manganese steel ,high chrome and martensite steel according to the hardness and feeding sizes of the material . We also can customize the overall dimensions and materials according to custom drawings and requirements.

Blow Bar

Blow bars are thick slab of metal inserts into the rotor and when the rotor spins high speed the blow bar repeated striking the material to the impact plates, during this process the blow bar fractures the materials until it meets the appropriate size fall through the impact crusher chamber.

It is also call as Impact Hammer or Impactor Hammer, mixture with Chrome, Manganese, Molly, Nikker and other alloys with different formula and heat treatments for materials like Granite, Limestone, Sandstone, Asphalt and concrete as etc.

Blow bar is a critical part during the crushing process, It is mainly made of high chrome alloy ,which are refined through special treatment and suitable for various applications like aggregates, coal, construction waste recycling. It has the best Micro-grain structure and sufficient toughness after quenching and tempering heat treatment,and the Hardness can reach HRC 60.

We offers high manganese, high chrome, High chrome with ceramic inserts, Martensite, martensite with ceramic inserts blow bars for varies needs, with high hardness, long wear resistance and strong toughness without breaking.

Impact Rack | Apron

The Impact rack is a Arc frame accommodate on the impact upper body, which combined with rod and spring to adjust the spaces of the crushing chamber. Normally the impact plates are seating on it to protecting the rack. But Untimely changing or bad quality of the impact plates could damage the rack. We casting high manganese steel impact rack instead of welding to maximizing the lifespan of your equipment for a more efficient aggregate and mining processing operation.

We provides OEM standard impact racks to many brands in order to perfectly adapt the attaching system and ensure the and service life of the accessories and increase the production capacity.

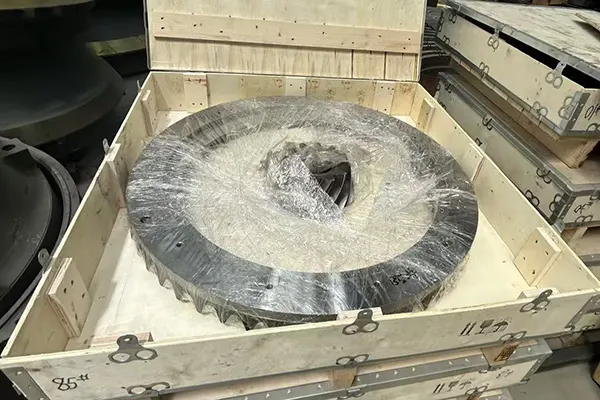

Rotor

The rotor is welded by thick steel plate, thick-walled pipe and casting. The main shaft and the rotor are connected by a flat key. The structure is simple, easy to disassemble and assemble.

The efficiency of the rotor designed by Yihong is 80% higher, and it can run smoothly even in the environment of minus 20–30℃, so it is very suitable for high-speed, variable load and impact occasions.