Jaw crusher spare parts is manufactured with high manganese steel Mn14Cr2, Mn18Cr2, Mn22Cr2 or Manganese steel with special alloy and heat-treatment process. JAW CRUSHER SPARE PARTS has a working life of 10%-15% longer than those made of traditional manganese steel. As per the feedback from customers, the good performance of jaw crusher spare parts in different working condition greatly decreased the time of examination & repair and the use-cost.

| Available models for Jaw crushers |

|

C Series |

C80, C96, C106, C116, C120, C130, C150, C160, C200 |

|

CJ Series |

CJ815, CJ615, CJ613, CJ612, CJ412, CJ411, CJ409, CJ211 |

|

JC/JW/JS Series |

JC2236, JC3660, JC5460, JW42, JW55, JS3750, JS4552 |

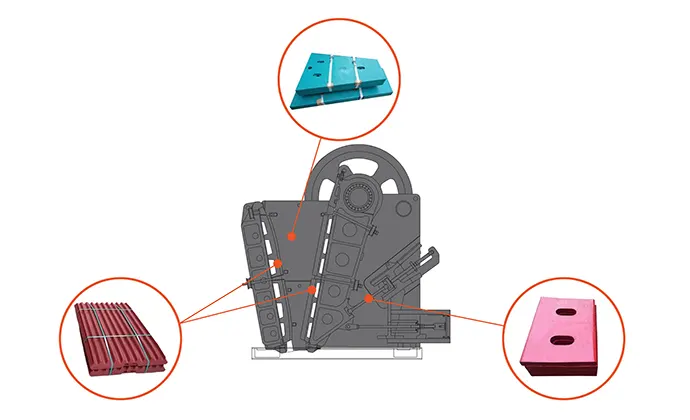

Jaw Plate

Jaw Plate are the most frequently replaced wear parts of Jaw crusher, The quality of the jaw die is important factors to reduce the crushing cost and efficiency by increasing operation time.

You can now choose from our production of various graded manganese steel crusher jaws:

Mn14Cr2: It is designed to crush soft stones from non-abrasive blasted rock, gravel, and round rock. For increased durability, consider using it for more accessible, low-impact crushing operations.

Mn18Cr2: A popular choice for cone crusher liners, It is best used for crushing operators that crush complex and non-abrasive blasted rock, medium and non-abrasive blasted rocks, non-abrasive gravel, and round stones.

Mn22Cr2: It is specially designed for crushing rigid, stubborn, abrasive stones. It’s recommended if you want a crush liner with increased span life.

Side Plate

The cheek plate or side plate is lining at two sides of the jaw crusher cavity to be mount with Jaw frame by bolt and nut.

The Lining plates are subject to high stress abrasions during the crushing cycle and material flows, So the lower Side plates usually is wear faster than the upper side plates.

The Liner plate usually made with Manganese steel or Hardox steel plate according to the material requirement.If you have special requirements, you can always let us know for special customization.

Toggle Plate

Toggle Plate is a simple parts on the Toggle Assembly Usually made of Carbon Steel (Cast Iron).It works with the toggle bearings at two ends one accommodate on the Pitman and another on the toggle block to hold the lower parts of the jaw in position.

It also serves as a safety mechanism for the entire jaw, If something that cannot crush gets into the crushing chamber accidentally or the rock is too hard to crush, the toggle plate will broken and prevent the jaw frame especially the Pitman (Jaw stock) from further damage.